Aluminum is a critical component of many low-carbon technologies needed for the energy transition, such as batteries, carbon storage for low-carbon hydrogen, or wind turbines. As technology now stands, there is—and will be—no solar power without aluminum, which accounts for over 85 percent of solar photovoltaic (PV) technologies.

The aluminum industry has a competitiveness and high carbon problem

While the aluminum industry counts many producers, production capacity has plummeted in many countries in the last decade because of low global prices and intense competition. At the same time, high capital, energy, and input costs have limited the development of new aluminum production.

Aluminum production also has a large carbon emissions footprint, emitting bout 1.1 billion tons of CO2 annually. The World Bank estimates that under the International Energy Agency's 2-degree scenario, total emissions from aluminum for solar PV could be as much as 840 MtCO2e—more than Germany's total emissions in 2019.

Key findings

A new report by the World Bank’s Climate-Smart Mining (CSM), Competitiveness of Global Aluminum Supply Chains Under Carbon Pricing Scenarios for Solar PV, examines aluminum competitiveness in the context of potential carbon prices.

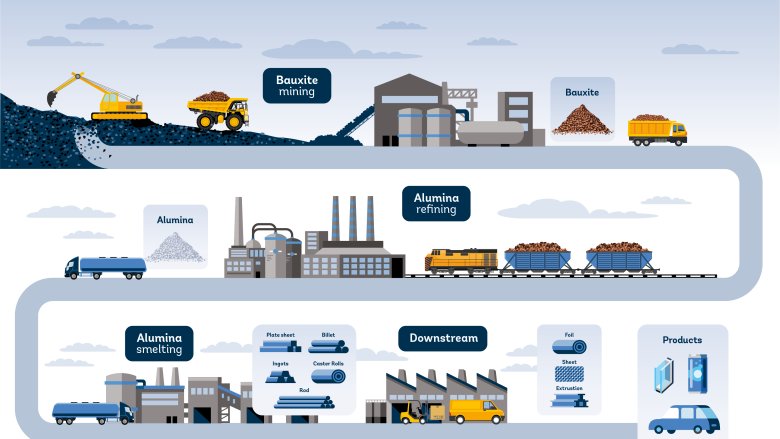

A key takeaway is that decarbonization across the aluminum supply chain is essential to retaining competitiveness and diversifying supply. Decarbonizing the entire aluminum value chain—beyond electricity used to produce the metal—is critical to reducing emissions to the largest extent possible and ensuring that producers, including in low- and middle-income countries, can compete in an increasingly carbon-constrained world.